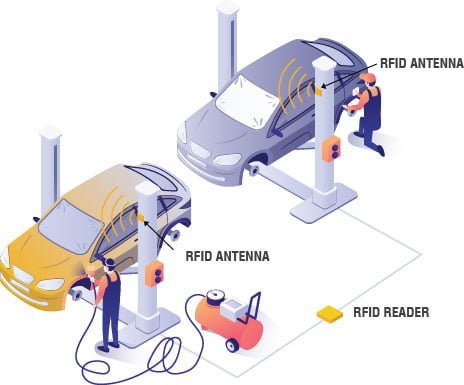

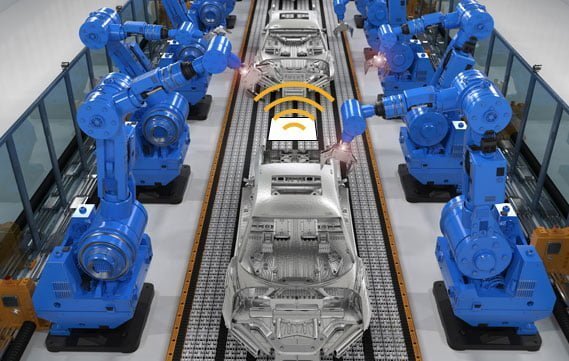

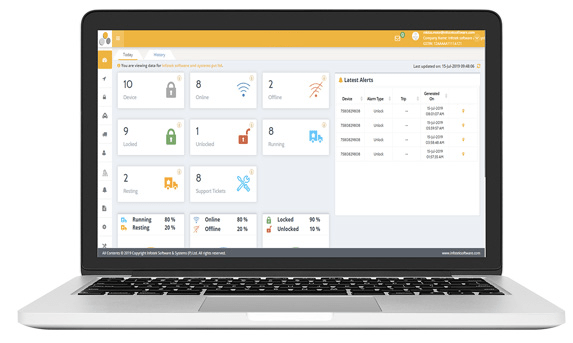

Enabling RFID technology to track work in progress (WIP) during manufacturing production provides vital data that can be accessed in real-time to give managers greater visibility into the production process. Most manufacturing environments require products to go through a series of distinct assembly stages. The subassemblies or raw materials become WIP and are passed from one station (or location) to another. This is where VF&T’s cloud and RFID based WIP Tracking Solution provides the advantage as each WIP can be uniquely identified using RFID tags.

As manufacturers strive for a lean, agile manufacturing plant, VF&T’s WIP solutions give them real-time visibility and tracking they need to keep up with the speed of competition and comply with their customer’s needs. Complex and large-scale manufacturing entail constant monitoring of process and tracking WIP and inventory. This can be carried out successfully using RFID tags which bring a lot of transparency and traceability in the processes. These tags can be deployed to help in management of all assets on the assembly line from manufacturing machinery, equipment and tools to WIP and final goods produced. They help in data collection, maintaining accurate reports and records, finding inconsistencies in process or quality, tracking rework and rejected material and even proper and accurate dispatches. These benefits lead to overall efficiencies and time savings in the production process.