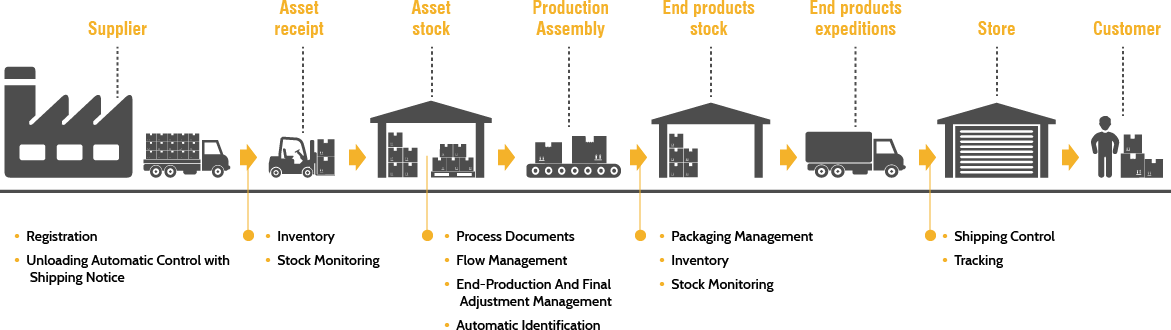

A supply chain is comprised of several tiers which include manufacturers, suppliers, transporters, warehouses, retailers, and the final customers. Warehouses are simply storage area where organizations store different products received from the suppliers and are part of supply chain. RFID plays a major role to enhance a more responsive control system for a supply chain ensuring complete end-to-end visibility.