Hospitals, hotels, laundry facilities, or any company with multiple types of textiles have a sorting process for laundering. With VF&T’s IoT Gateway, VF&T Belt, VF&T Pay, VF&T Handy, VF&T Write integrated with VF&T’s cloud and RFID based LMS (Laundry Management System) determines what type of textile is being read and directs it to the proper area or machine. The software’s findings can be displayed on a screen so that a person can immediately direct the textile or linen to its next destination.

Efficient identification of linen and the ability to track and trace pieces throughout the process line and even en route to and from the customers could be said to be at the heart of effective linen management.

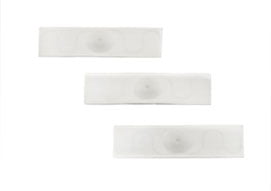

The textile, linen rental, and process industry has undergone high modernization in recent years and is more technologically advanced than ever before. Radio-frequency identification (RFID) technology is one of the latest advancements that is revolutionizing the sector and the VF&T solutions we offer our customers can take all the advantage of the fast and error-free processes.

Linen base industry units have also recognized that the use of RFID is going to be an increasing trend for their laundry customers and are promoting services that they can offer to assist.