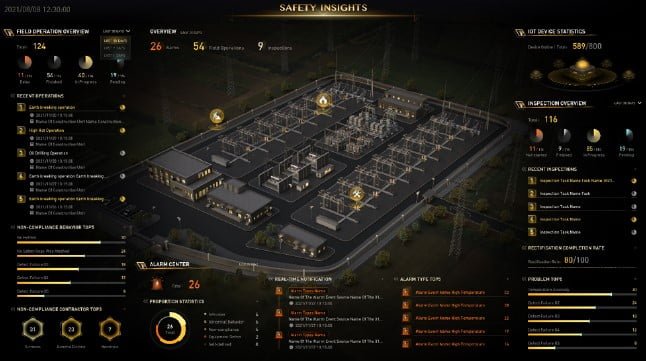

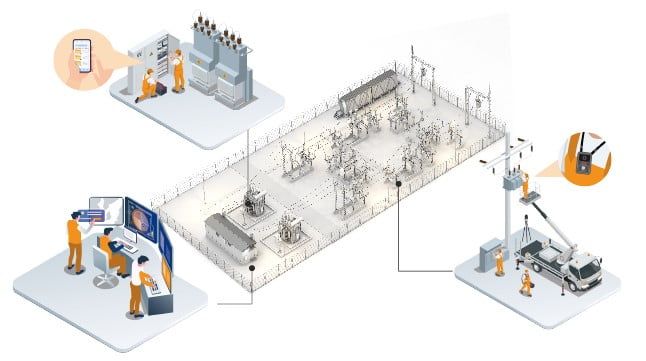

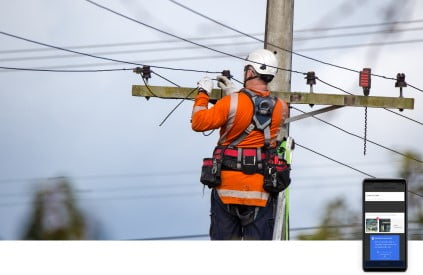

Keeping sites secure. Keeping production up and running. Keeping staff safe. These are the three major concerns for managers in the power and utilities industry, and the whole aim of VF&T’s solution.

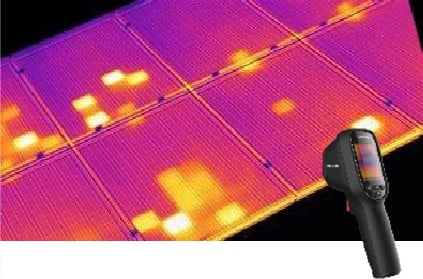

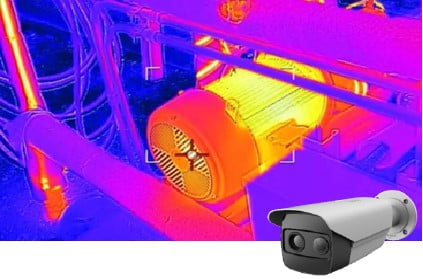

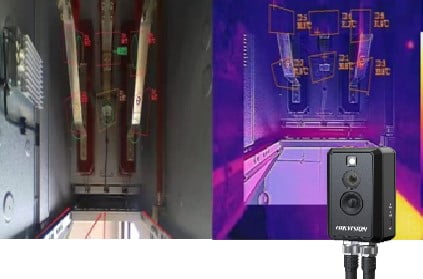

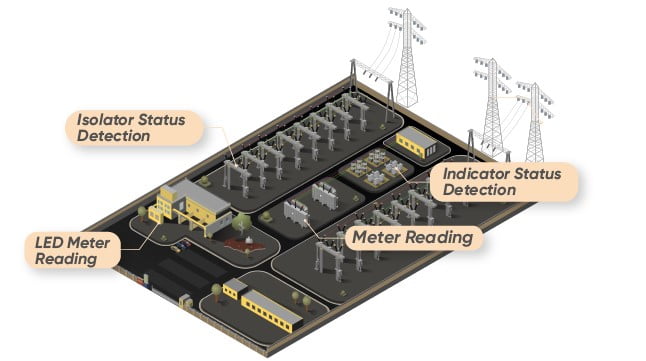

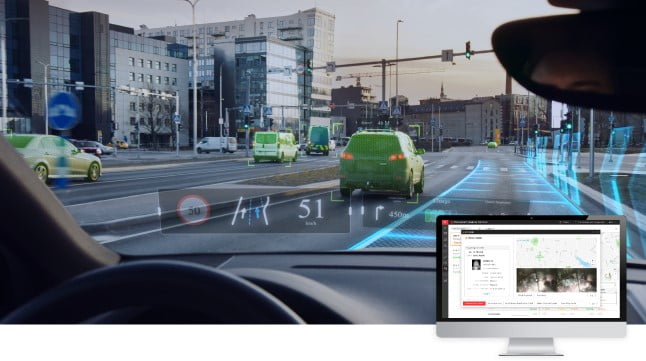

Today’s global energy demands present new challenges, requiring these sites to operate more effectively. That’s why VF&T’s end-to-end Solution for Power and Utilities harnesses world-leading security cameras, thermal technologies, and intelligent analytics, along with an amazing platform for third-party integration. VF&T provides robust and reliable security monitoring while empowering more efficient operations and timely maintenance.

Read on to learn how this solution can bring safety and intelligence to your unique scenario.