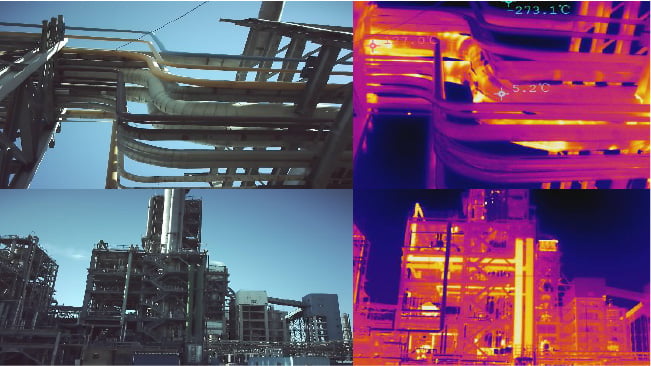

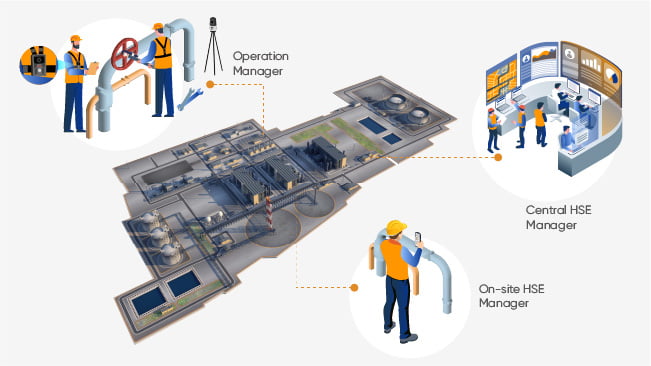

Due to the extreme hazards in oil and gas operations, safety and environmentally-friendly management remains the primary concern of administrators. Additionally, as an asset-intensive industry, the productivity of oil and gas relies heavily on reliability. Faced with these distinct challenges, you need intelligent solutions that answer the most concerning questions. That’s what we can do.

VF&T’s AI-powered Solution for the Oil & Gas Industry provides advanced technologies and products that empower your businesses and employees with unparalleled abilities to address every aspect of safeguarding and enhancing the oil and gas value chain.